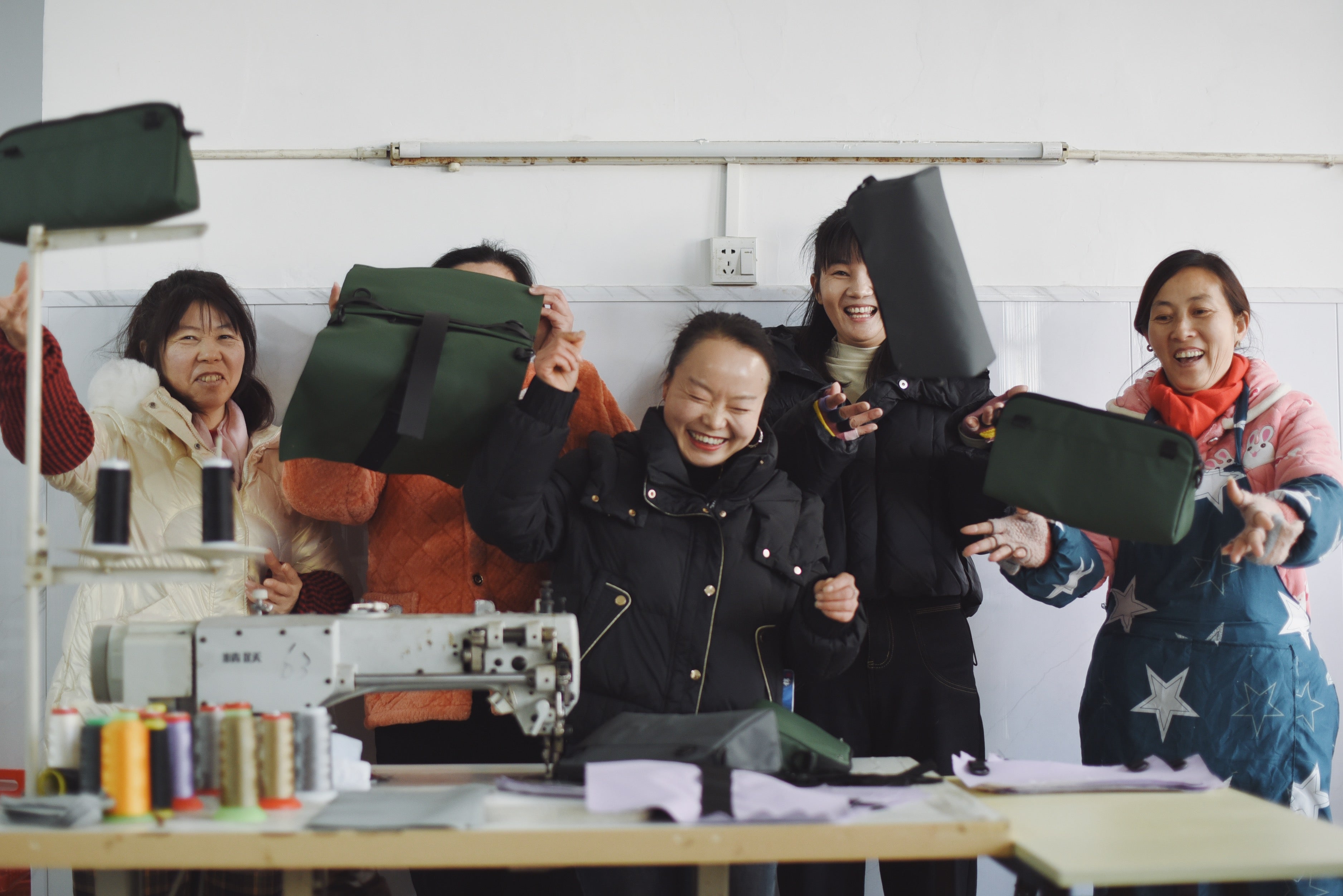

In 2025, we approach the 10th anniversary of KIWEE. Our mindset has shifted. We see KIWEE, including our products and our business partners, as part of a long-lasting, non-disposable system. Before we make any move, we think it through, set our standards, test them, and take our time. It’s all about building sustainability into everything we do.

For example, we aim for our bags to have a long life cycle as shown below.